Keck Graduate Institute - Aran Lab

Engineering Intern: Summer 2022

Skills: Solidworks, Ansys CFD, SLA, FDM, PDMS bonding, Silicone Molding, CNC, Bootstrap, SQL, QA

Overview:

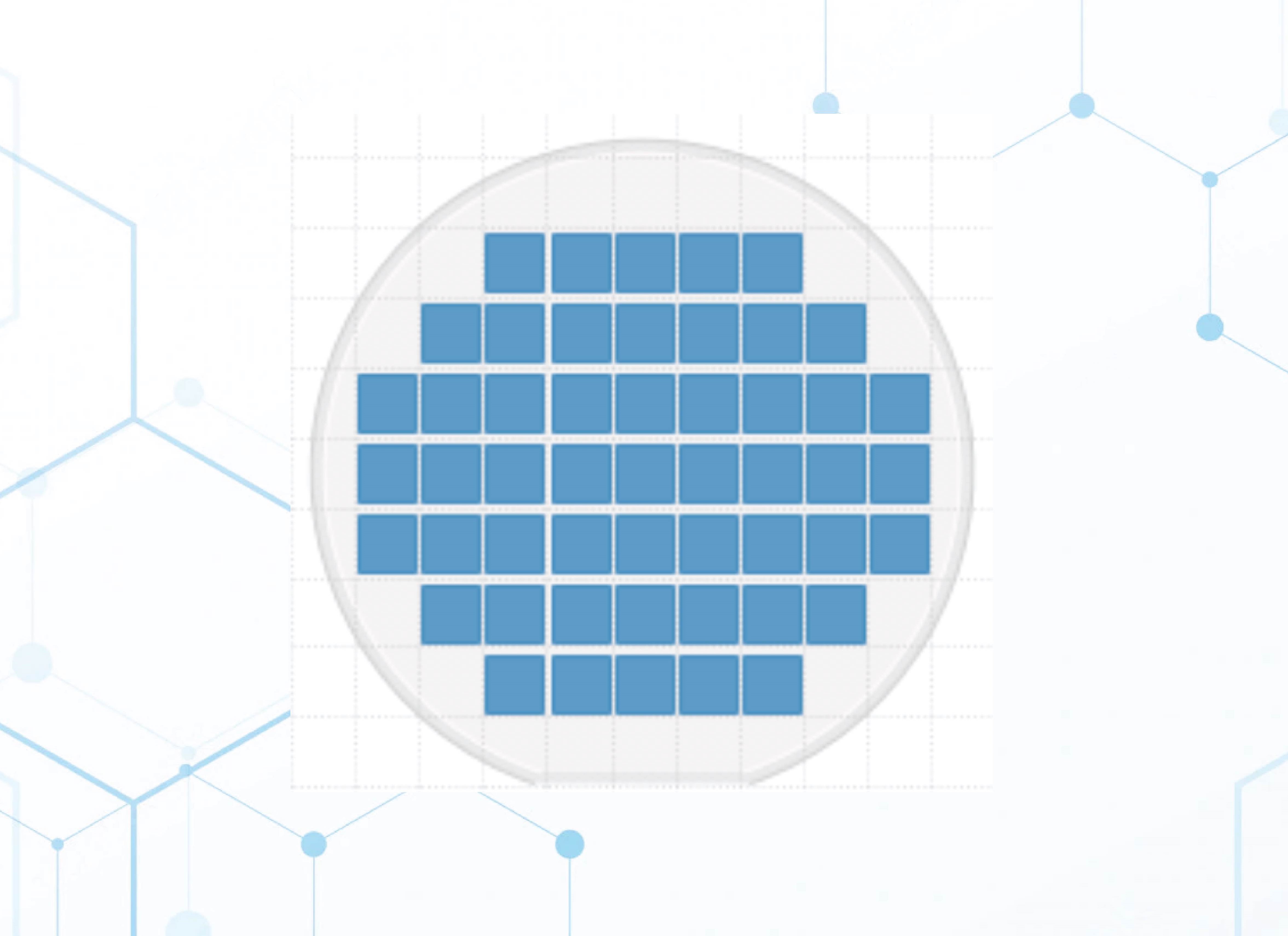

In Summer 2022, I interned at the Keck Graduate Institut'e Aran Lab which specializes in developing diagnostic biosensor chips. These chips can detect trace amounts of any protein or viral particle. My task was to design low-cost microfluidic flow cells that could facilitate mass-testing of chips, create a QA database website using Bootstrap and SQL, and run CAD + CFD workshops for the Undergraduate Medical Device Bootcamp. We pitched these microfluidic devices to Cardea Bio Inc., the producer of these chips, and they expressed interest in mass-producing our attachments for future use in testing their biosensors.

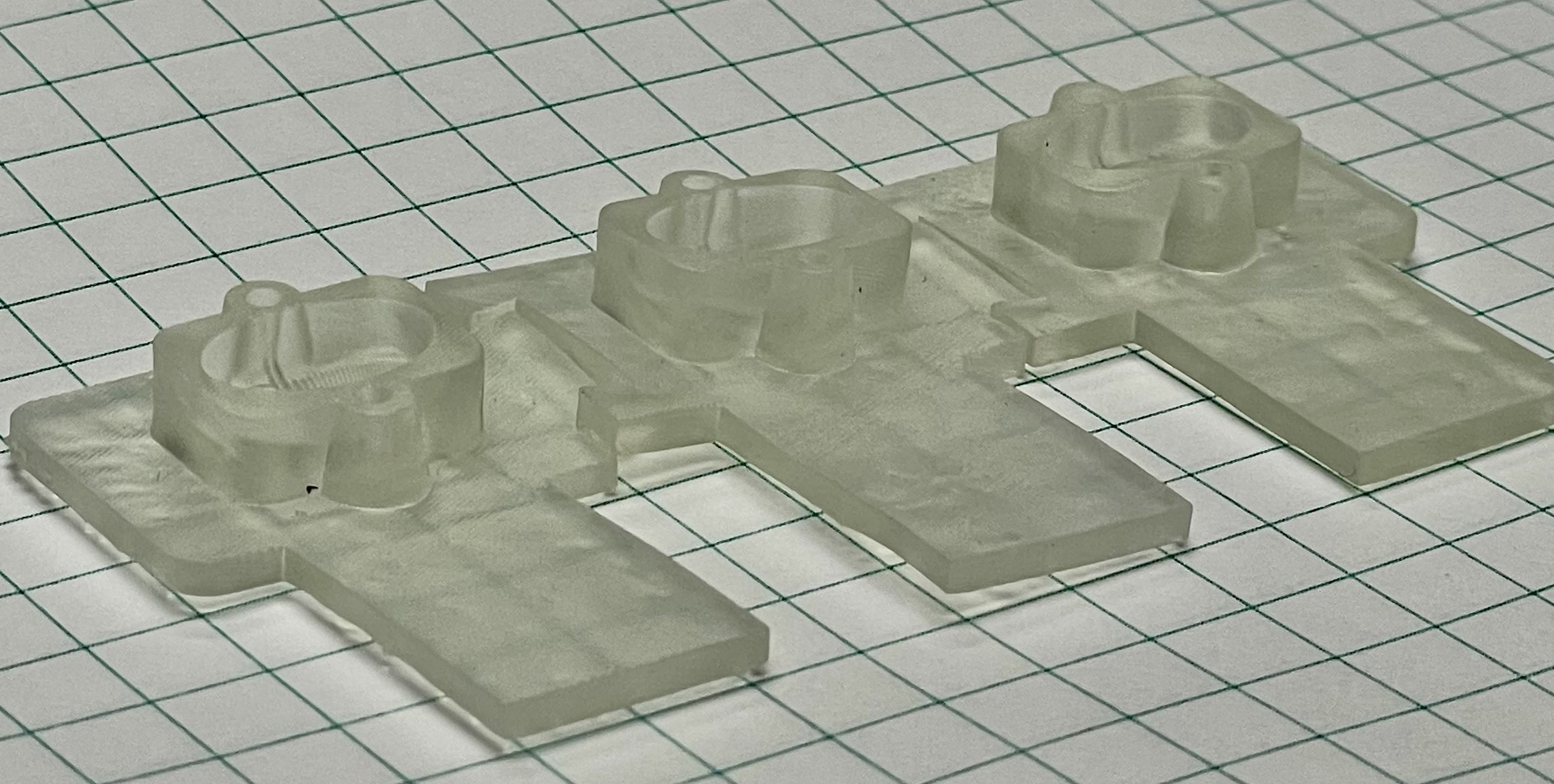

Project 1 - Microfluidic Flow Cells:

The purpose of these microfluidic devices were that they had to:

1. Have an inlet and an outlet for solutions

2. Locate themselves to align themselves in large assays

3. Allow for a film to be placed over the sensing reservoir and still let liquid through

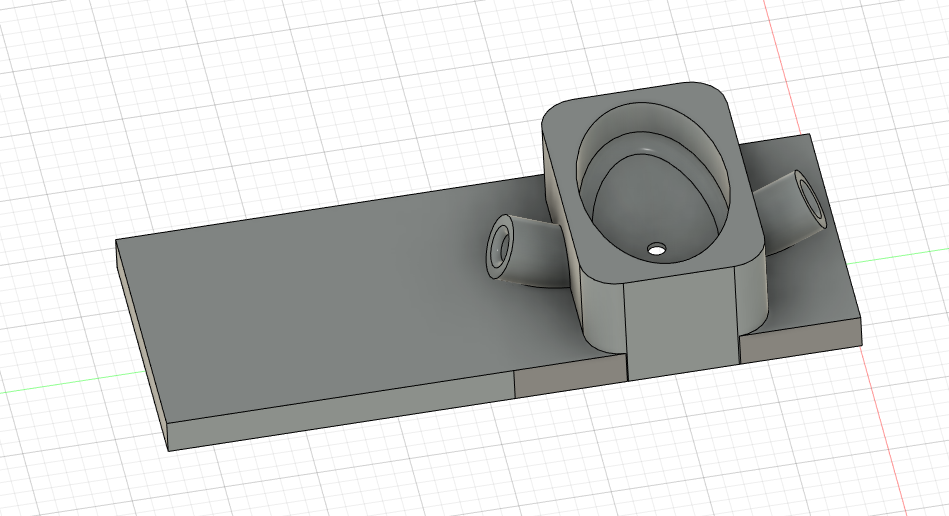

Our initial design utilized angled pipette inlets and air outlets, which later proved to be not user-friendly.

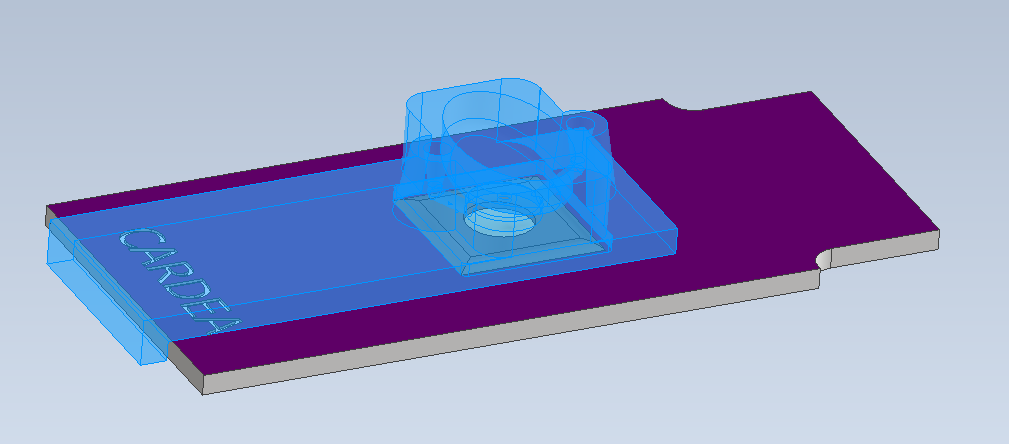

We also used interlocking dovetail systems to keep multiple attachments and sensors togther while testing large assays.

However, this caused accuracy issues. The buffer solution also got stuck easily on the unfilletted edges of the top chamber.

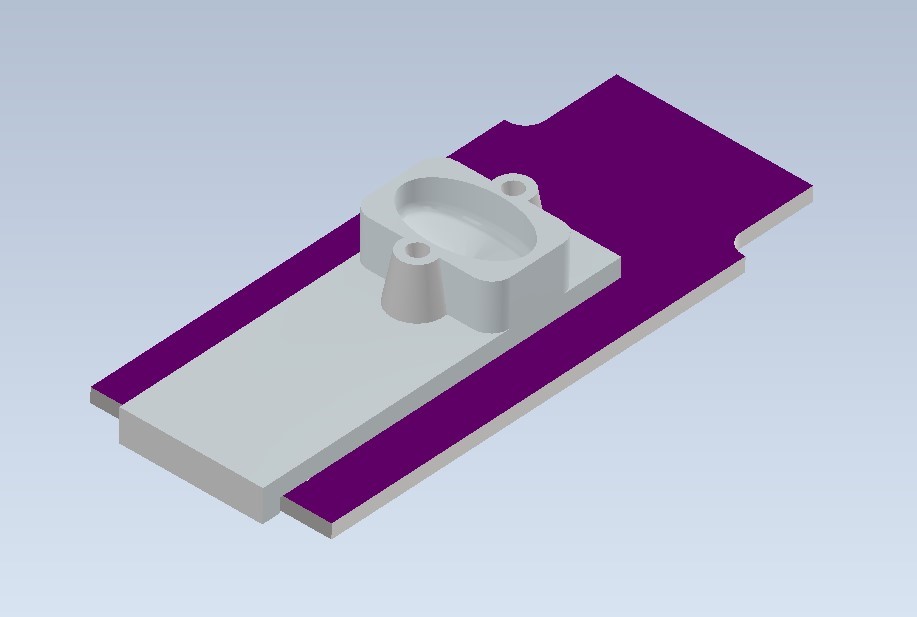

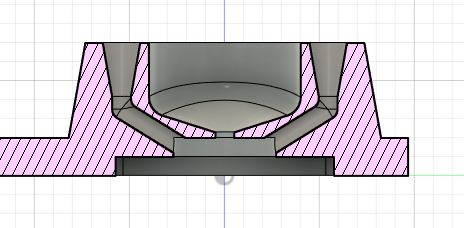

In our new design, we implemented vertical inlets with angeled pathways instead of angled inlets. This greatly improved the continuous

flow of liquid. We also put radiuses on the top chamber and got rid of the dovetail features. Instead, each attachment was datumed to

the bottom edge of each chip.