Eko Health

View PresentationCo-Lead for Sustainable Packaging Design Project

Skills: Project Management, Onshape, Figma, Adobe Dimension, Life Cycle Assessment, Cost Analysis

Project Overview

This was a project in collaboration with the medical device company, Eko Health. Their main product, the Core500 is a digital stethoscope that provides 4x sound amplification + active noise cancellation,

built in ECG wireless listening via Bluetooth, and allows users to record, save, and share audio. I co-led this project with a team of 7 engineers and designers to help redesign the Core500's packaging to

be more sustainable, cost-efficient, and unique in user experience.

Team: Allison Yuh, Jade Stashin, Adin Esberg, Michelle Gantos, Shannong Long, Yahany Francisco, and Zachary Zane.

Initial Steps

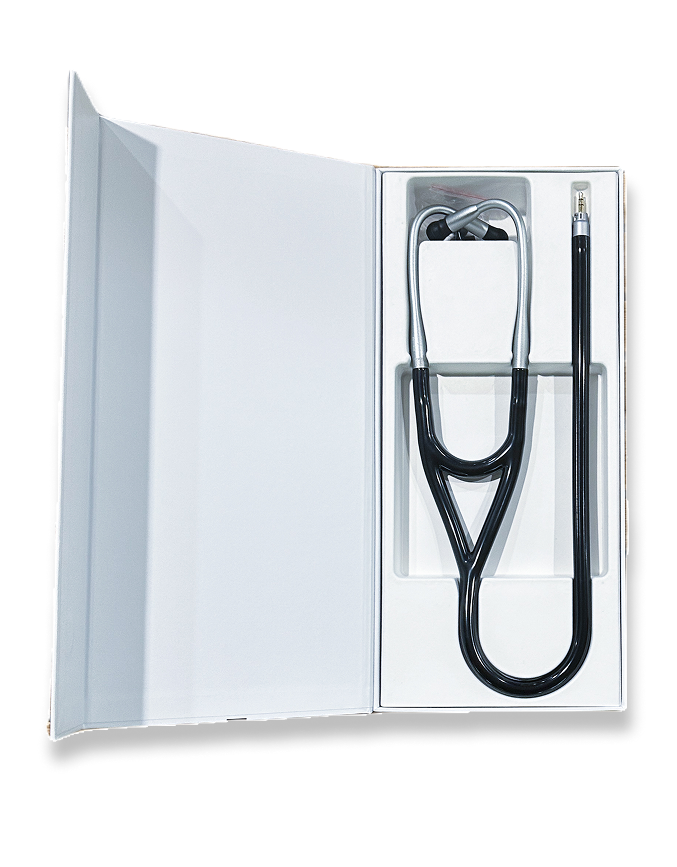

Pictured is the original Core500 packaging which comes in two separate pieces-- The stethoscope head + tubing. Eko asked us to

help with rebranding their packaging to create stronger customer-to-company relationships, make the pakaging more sustainable, and

lower the cost of production.

During our initial phase of the project, we delved into the medical industry and user perceptions of packaging and sustainable design.

We conducted 80 user surveys to gauge user interest and preferences, ranging from doctors, to vets, to nurses, to educators.

We also researched various sustainable materials to eliminate the current packaging's use of magnets, excess water consumption during production,

and other pricey or toxic materials.

Ideation

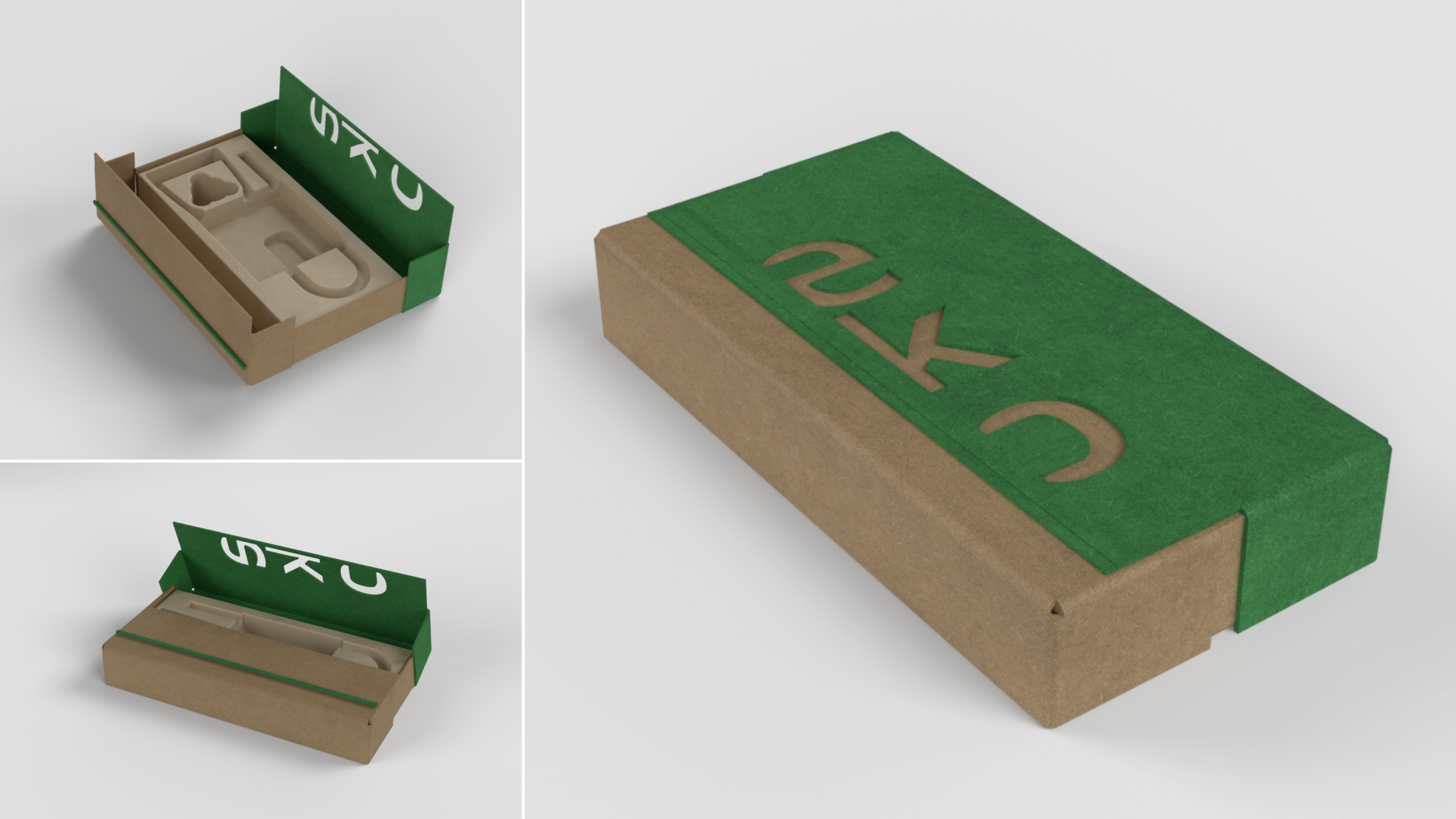

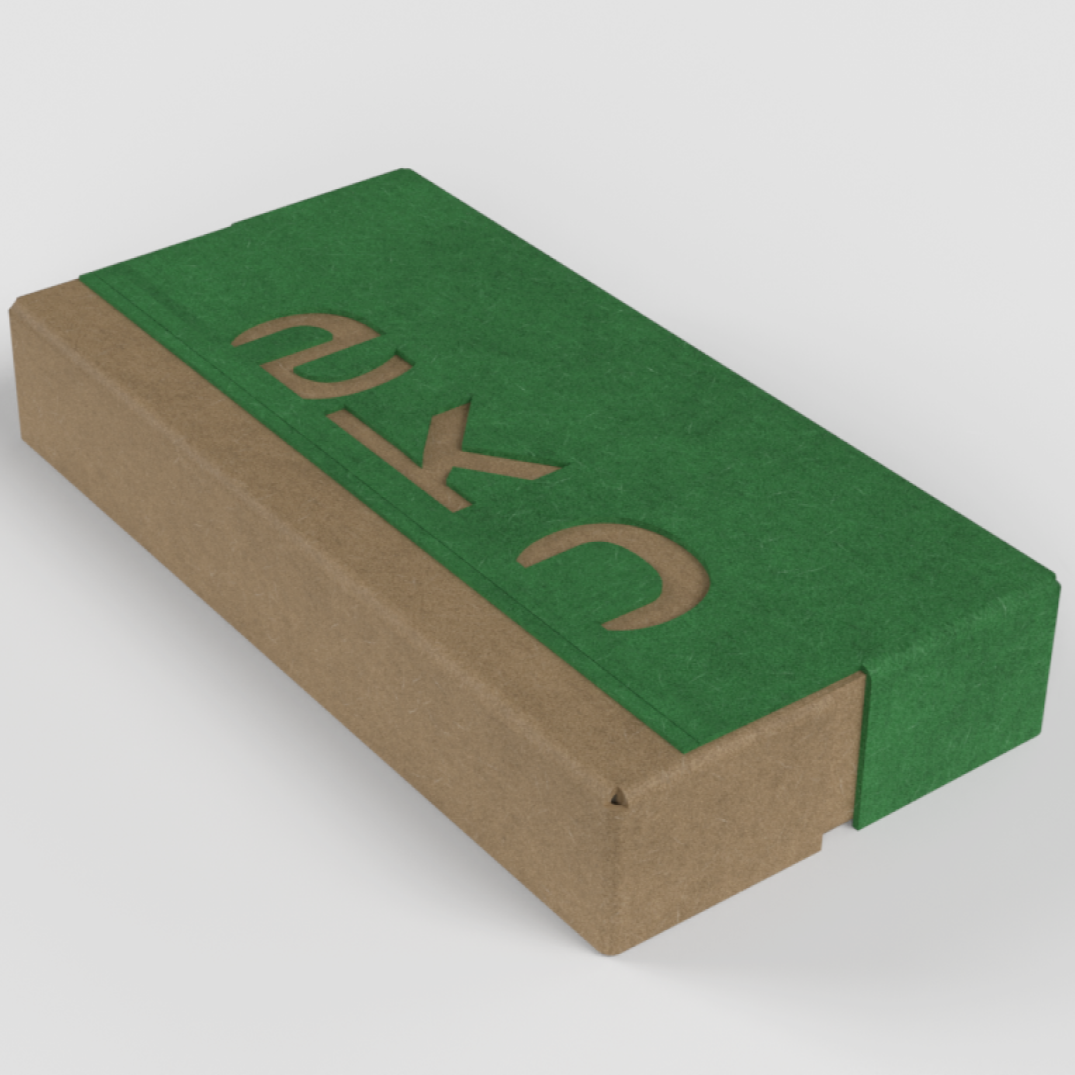

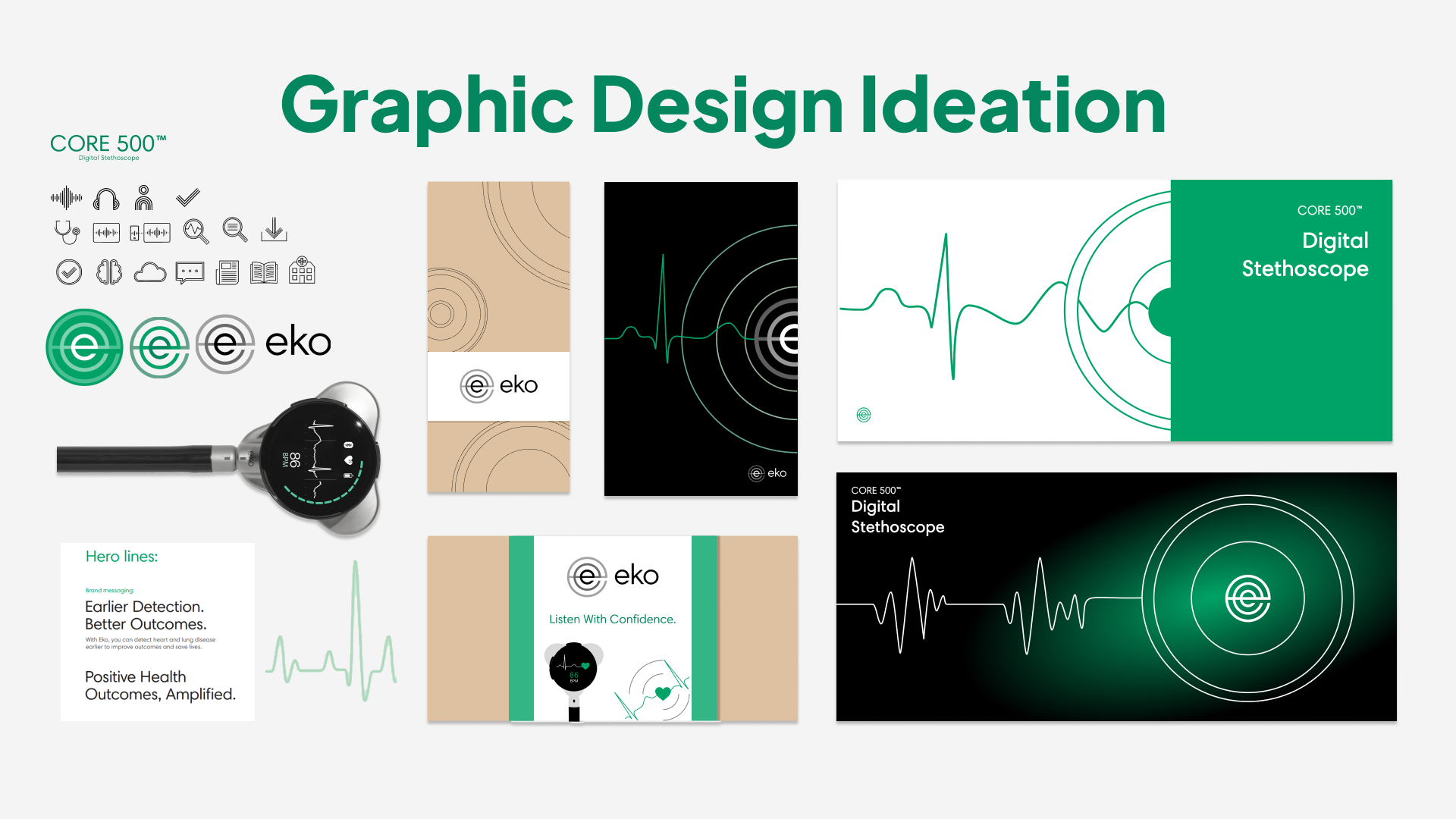

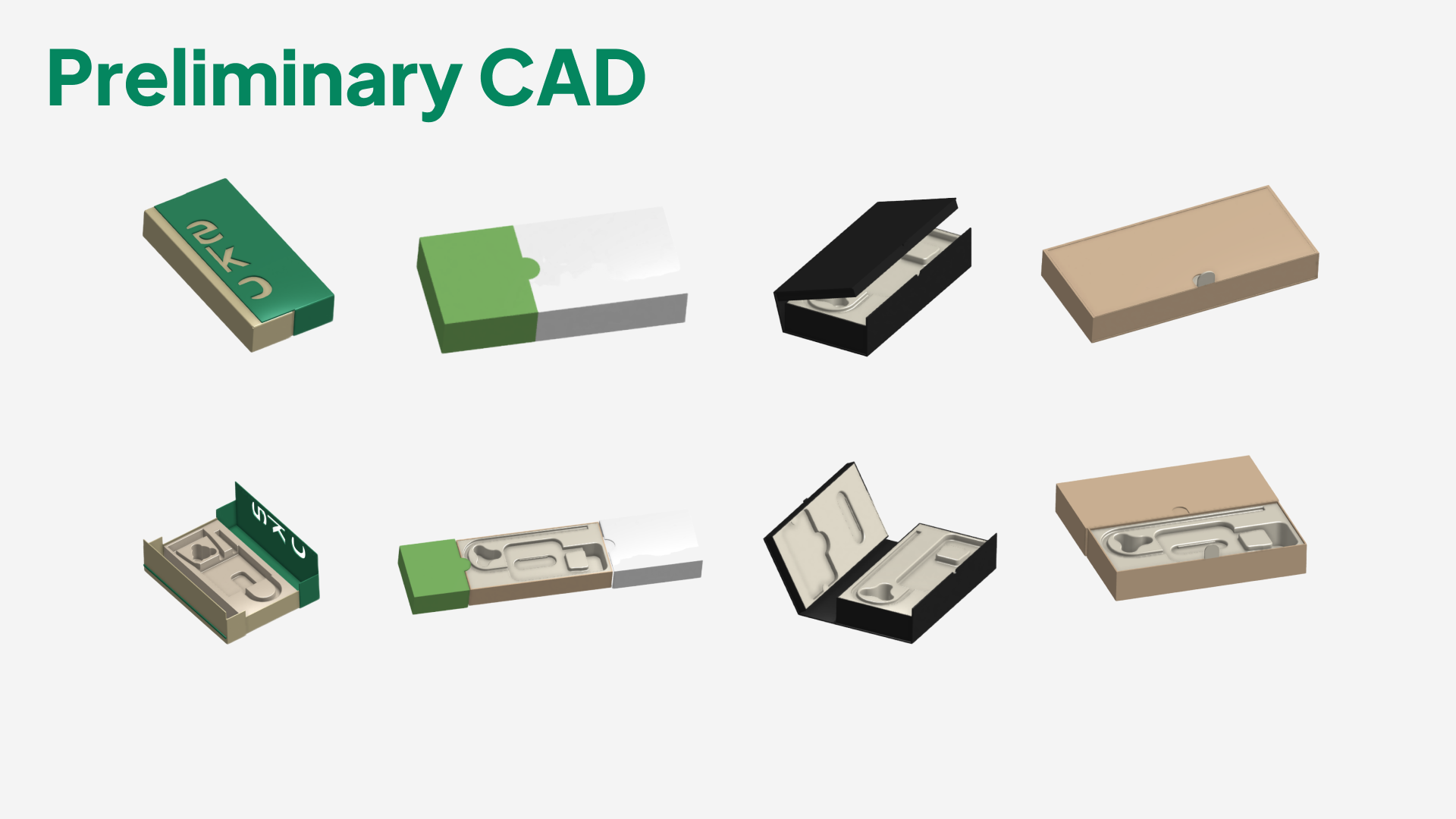

During our ideation process, we used mood boards to create new inspiration for the brand. We also used Onshape to CAD our different layouts and optimized space/material use. We also use Figma for graphic design ideation and used Adobe Dimension to render any ideas we had. Taken from our final deliverable, these images show our design process.

Analysis

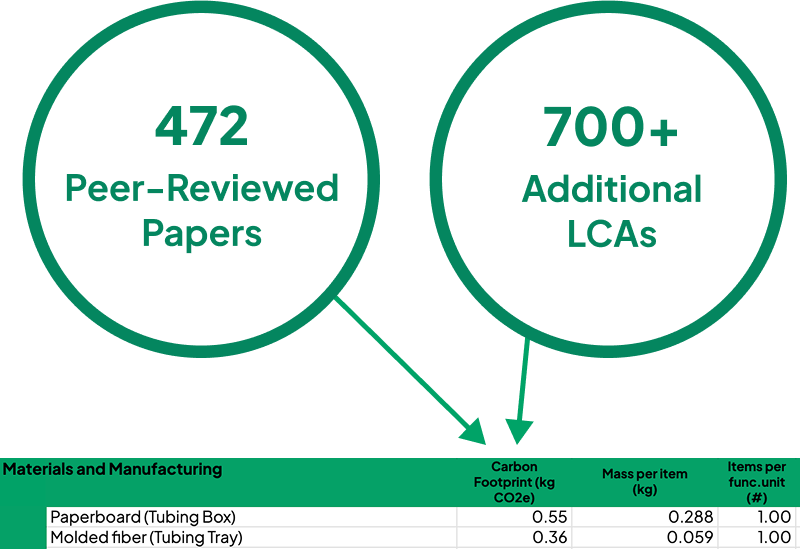

We aimed to reduce the kg/CO2 eq of each packaging design from material extraction to end-of-life. We foxued on materials and manufacturing, using

a simplified version of the Industrial Design & Engineering Materials (IDEMAT) Database.

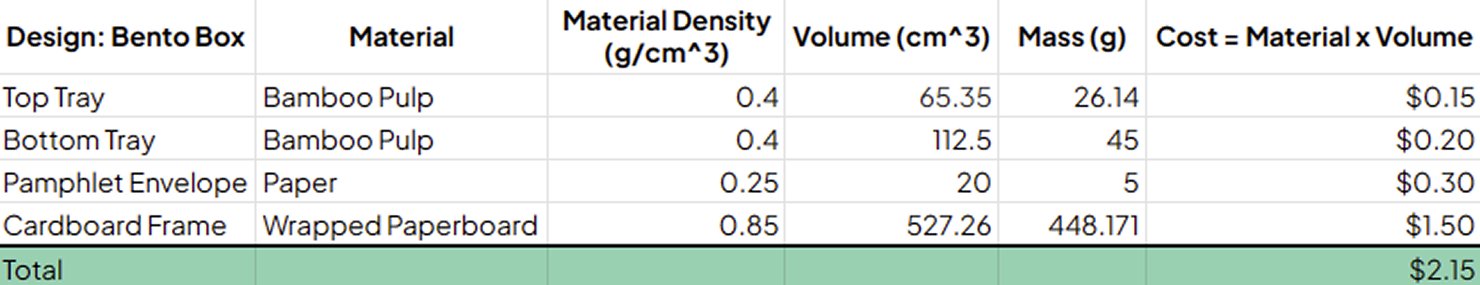

We also used indsutry trends to approximate total costs for manufacturing and packaging expenses to analyze cost performacne. By commonizing many

of the materials use in each packaging concept, we were able to reduce total costs.

Final Designs

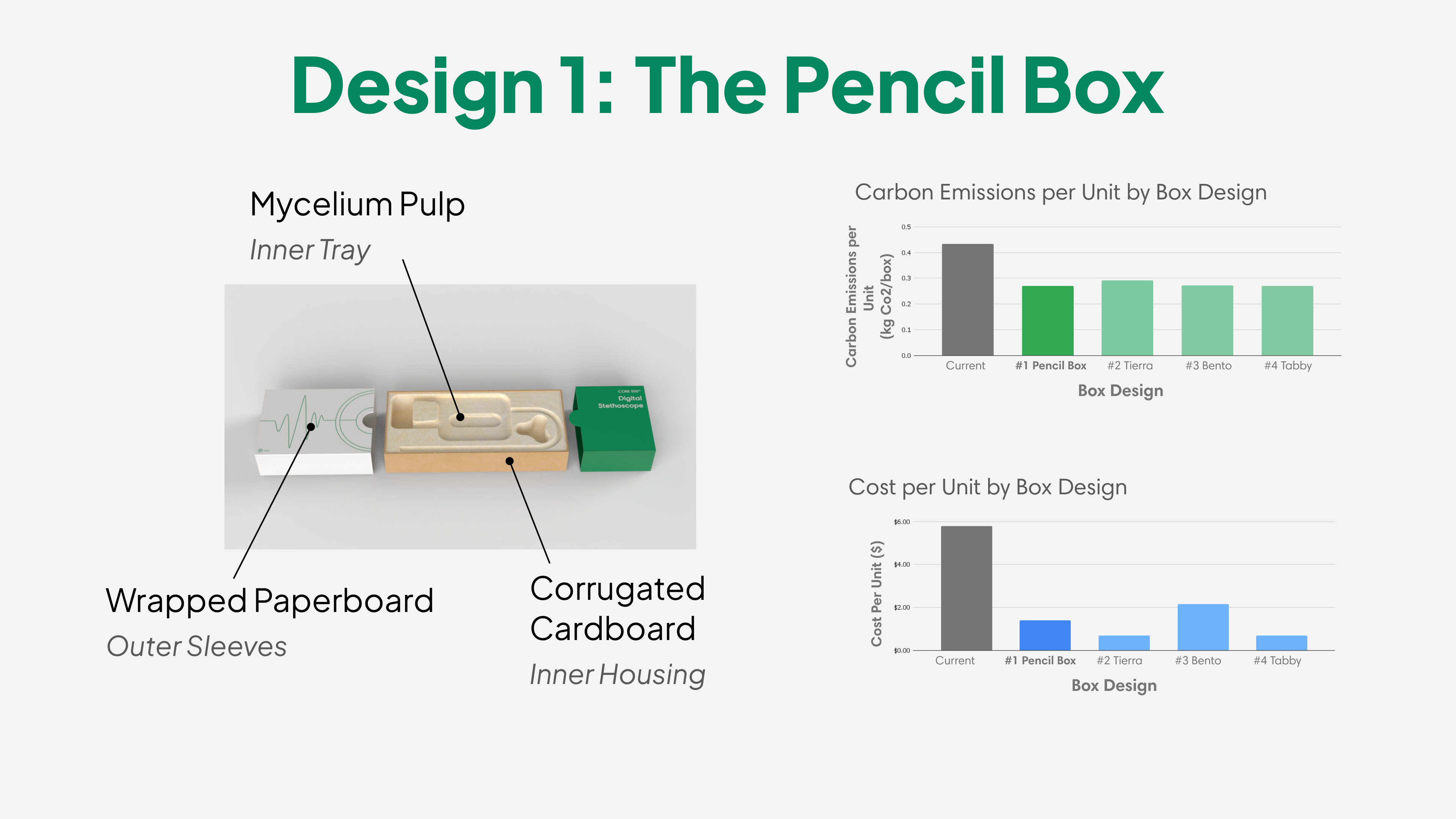

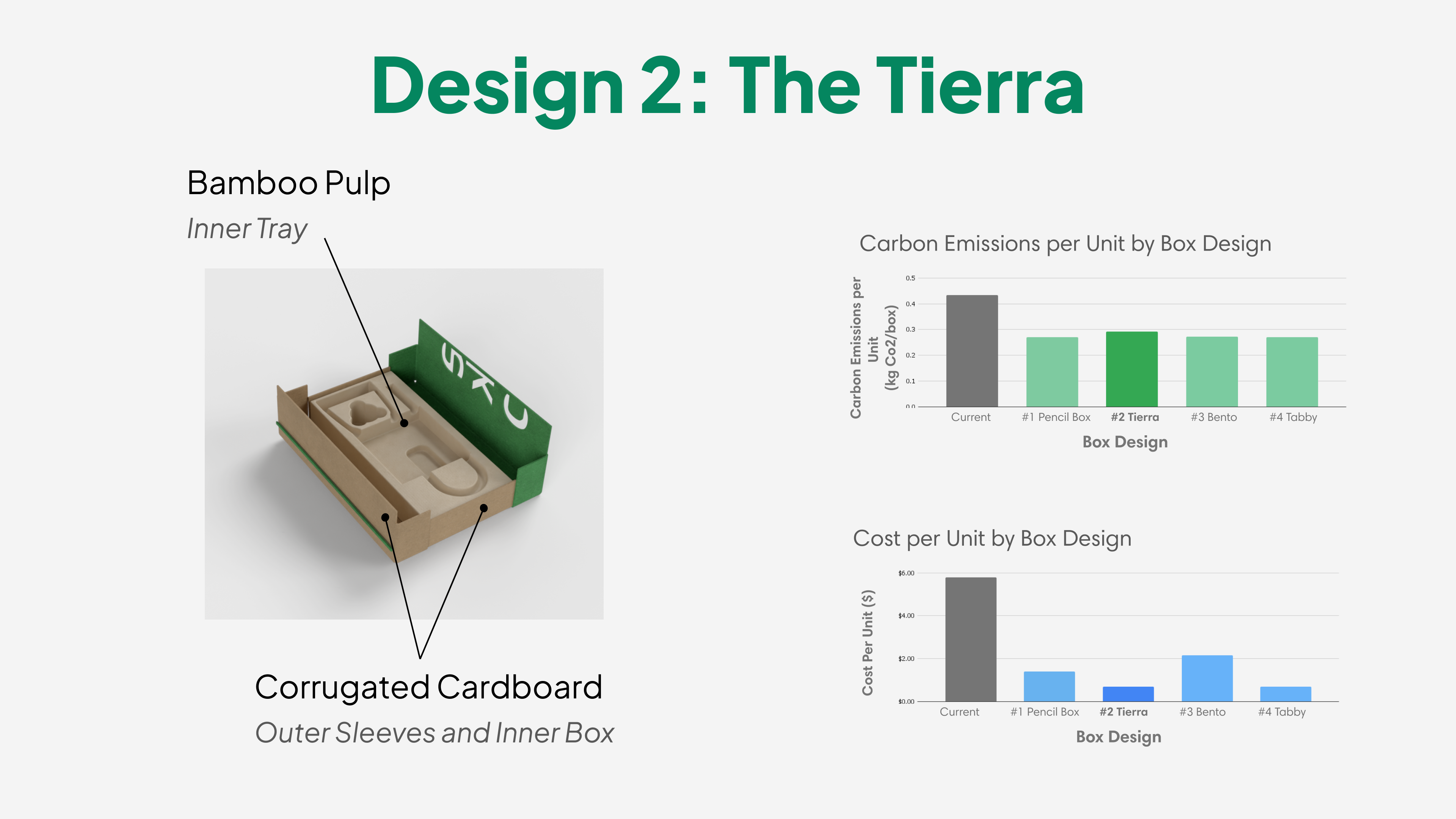

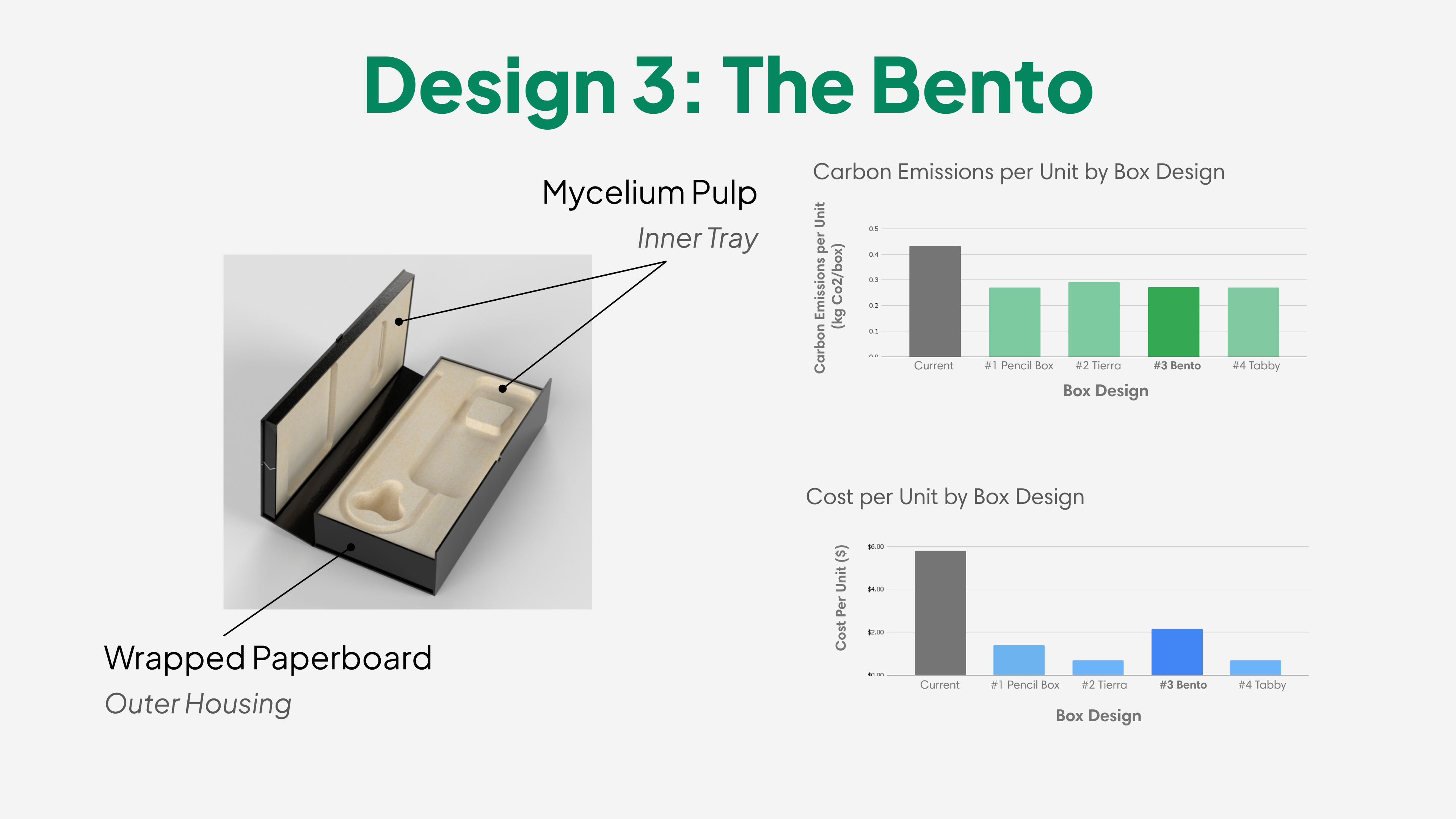

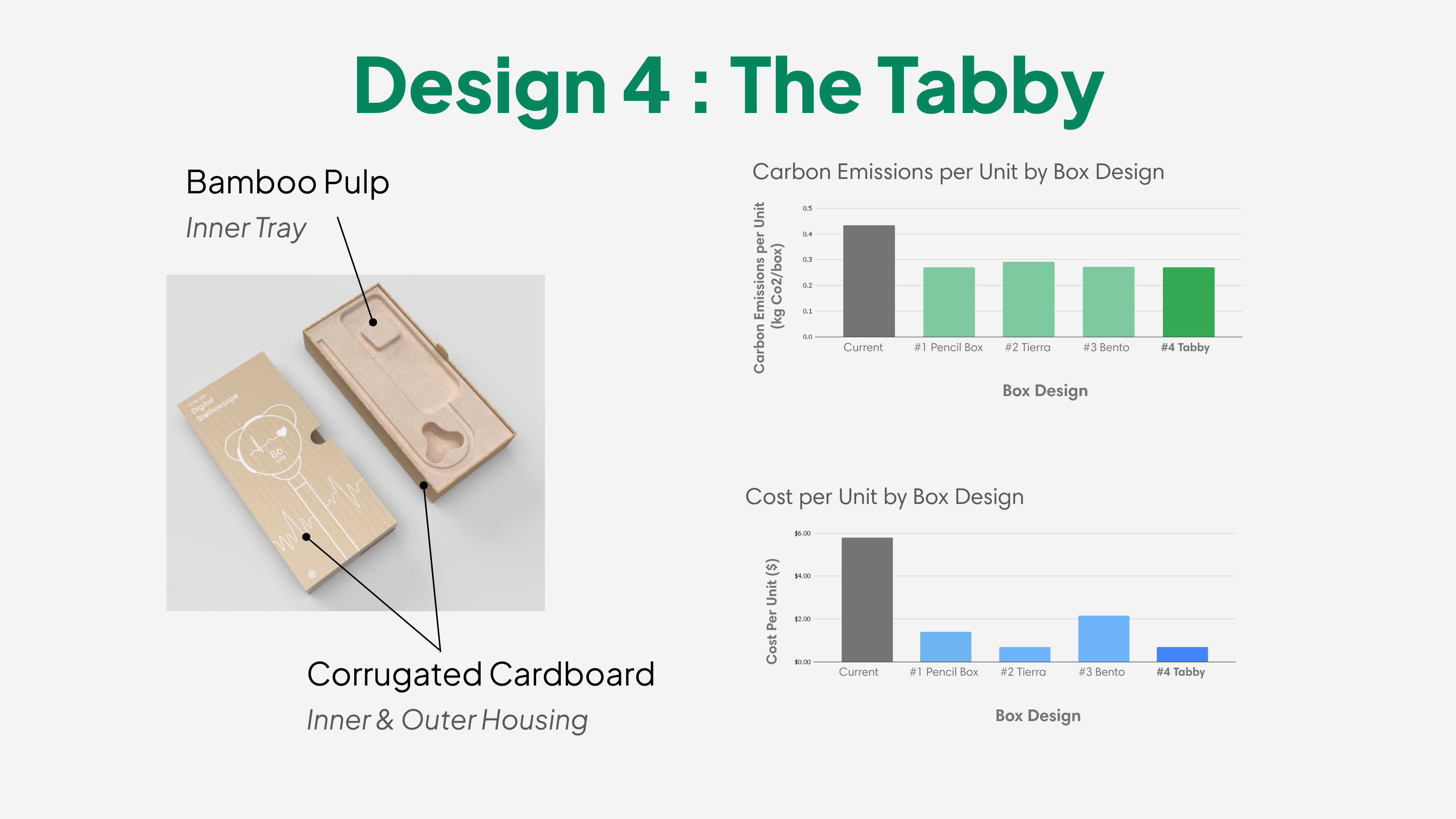

We came up with four final designs, with the Bento being heavily preferred by the head executives at Eko. Each design was analyzed and seen to have at least 30% reduction in carbon emissions and 50% reduction in cost.