Navier

View PresentationEngineer for Hydrodynamic Sonar System Project

Skills: Solidworks, Ansys CFD, DFMA, 3D Printing, Machining

Project Overview

This was a project in collaboration with the electric hydro-foiling boat company, Navier.

I worked as a Mechanical Engineering Consultant and was tasked to research, develop, and test a sonar enclosure and deployable mount. Our three main objectives were:

1. Create an acoustically transparent sonar pod fairing to house the sonar (Gramin PS51) + electronics

2. Design and machine an external and deployable mount for the sonar pod

3. Ensure the design is fully removable and is hydrodynamic

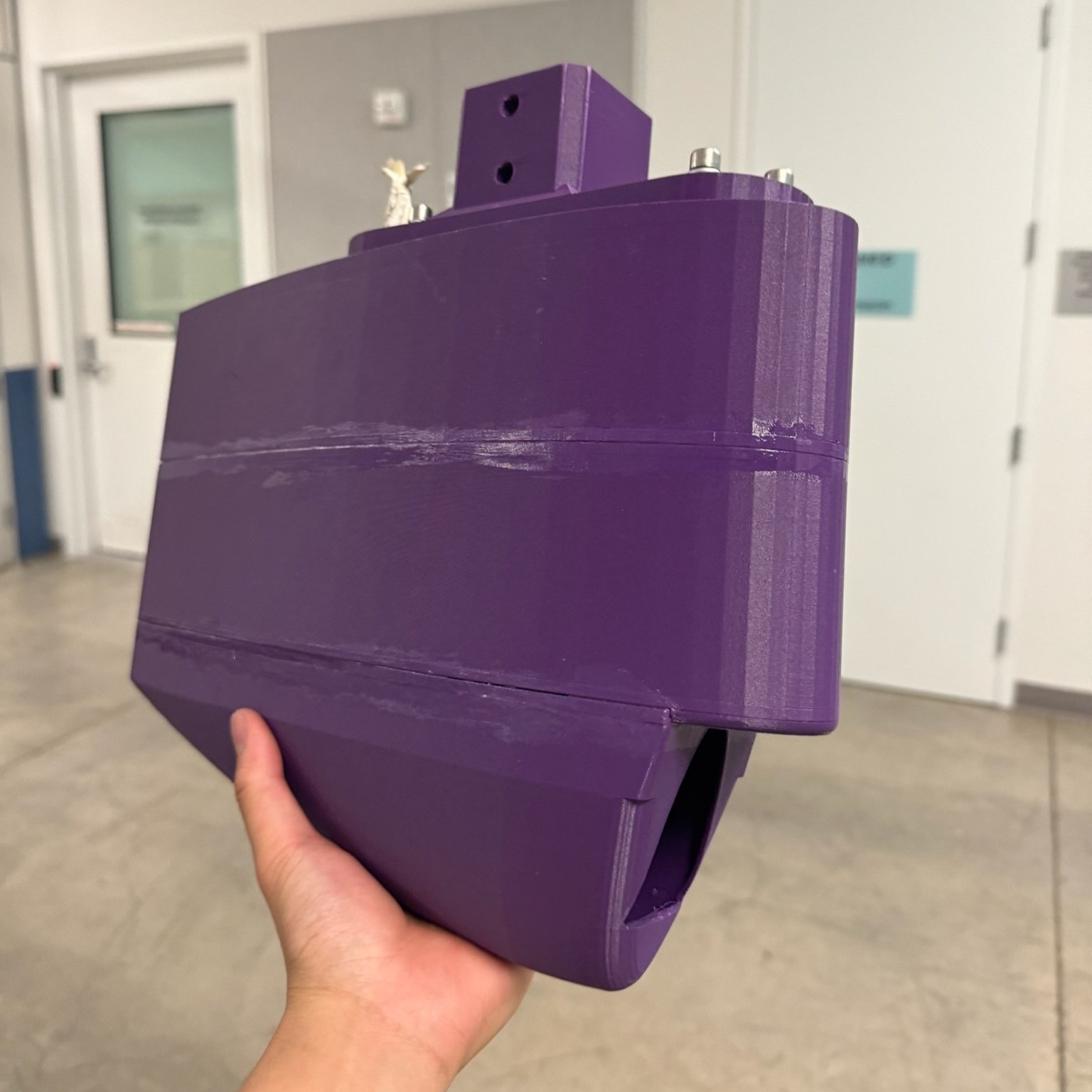

I was the responsible engineer for creating the sonar pod fairing that houses the forward facing sonar, and saw the design through to production and delivery.

Material Selection

Requirements for the sonar pod included acoustic transparency, corrosion resistance, mechanical strength, low resonance, and high strength-to-weight ratio. Since our sonar was a through-hull sonar, we decided to go with a material that was acoustiacally transparent and easy to use and manufacture with. From reading literature and doing research, we found that polymers were the best in terms of acoustic transparency and that composite materials would provide the highest strength- to-weight ratio. We also found 3D printing to be the most viable manufacturing option for us, so we decided to use Carbon Fiber PETG.

Hydrodynamics

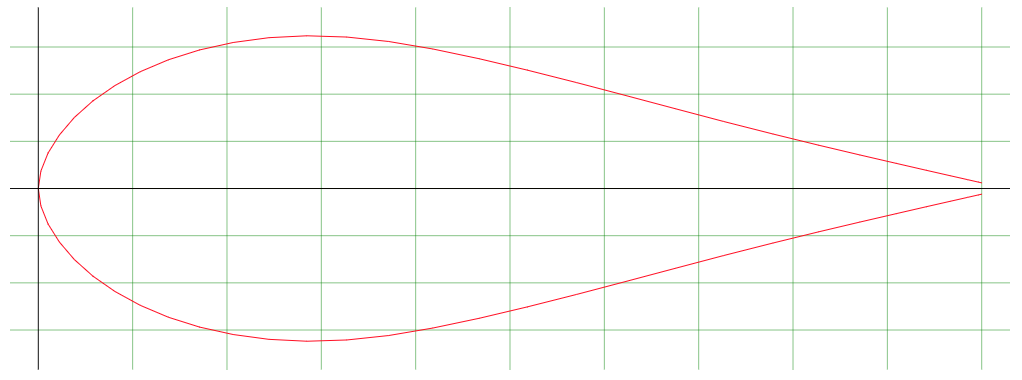

Our sonar fairing had to be hydrodynamic, yet strong and protect the electronics from its environment. Since the fairing would be mounted to the front of the boat and would

be the first to break and water as it accelerates, we needed a fairing with a profile on both the XY-plane and the XZ-plane cross sections. We were also limited in its width by

our 3D print bed's dimensions and had to opt for the smallest foil possible for our sonar.

Since we did not want to generate any lift, we decided to go with a symmetrical foil type, modeling after the Eppler 862.

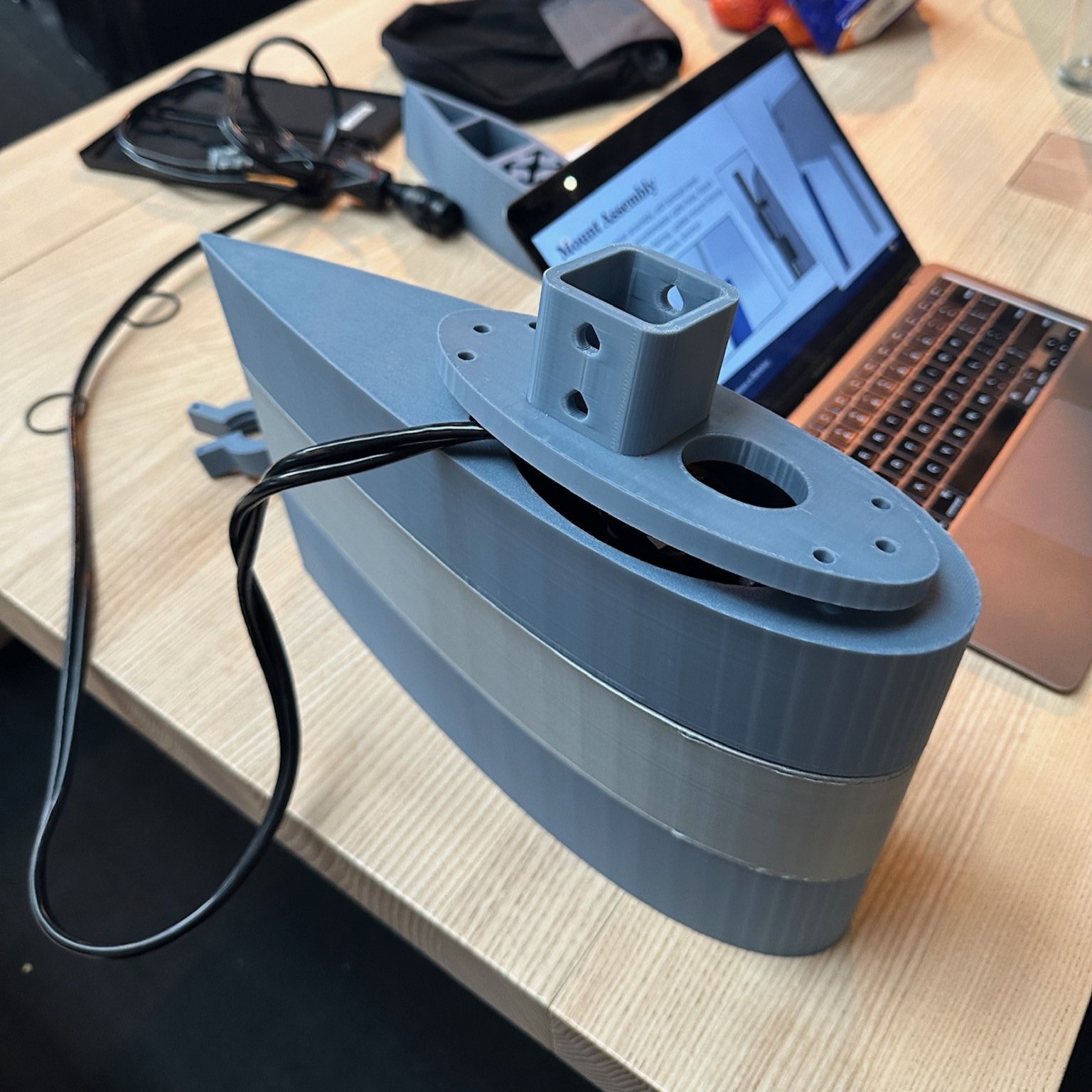

Since the sonar pod was quite tall, we decided to split the pod into 3 main sections that were all 3D printable and were secured using plastic welding.

CFD Simulations

We ran Ansys CFD simulations to validate our designs. Using both 3D and 2D simulations, we were able to optimize our drag coefficients and minimize pressure forces.Design Changes

Originally, the design did not have a cutout for the sonar face, but after thorough testing, we found that better readings came from the design with a cut-away. Although it came with the cost of increased drag, the tradeoff for better readings was decided as the best option by Navier engineers. Pictured is our final pod design.

Mounting

The pod was required to be consistently underwater throughout travel. Since the N30 is a foiling boat, it rises out of the water periodically, requiring the mount to be quite long.

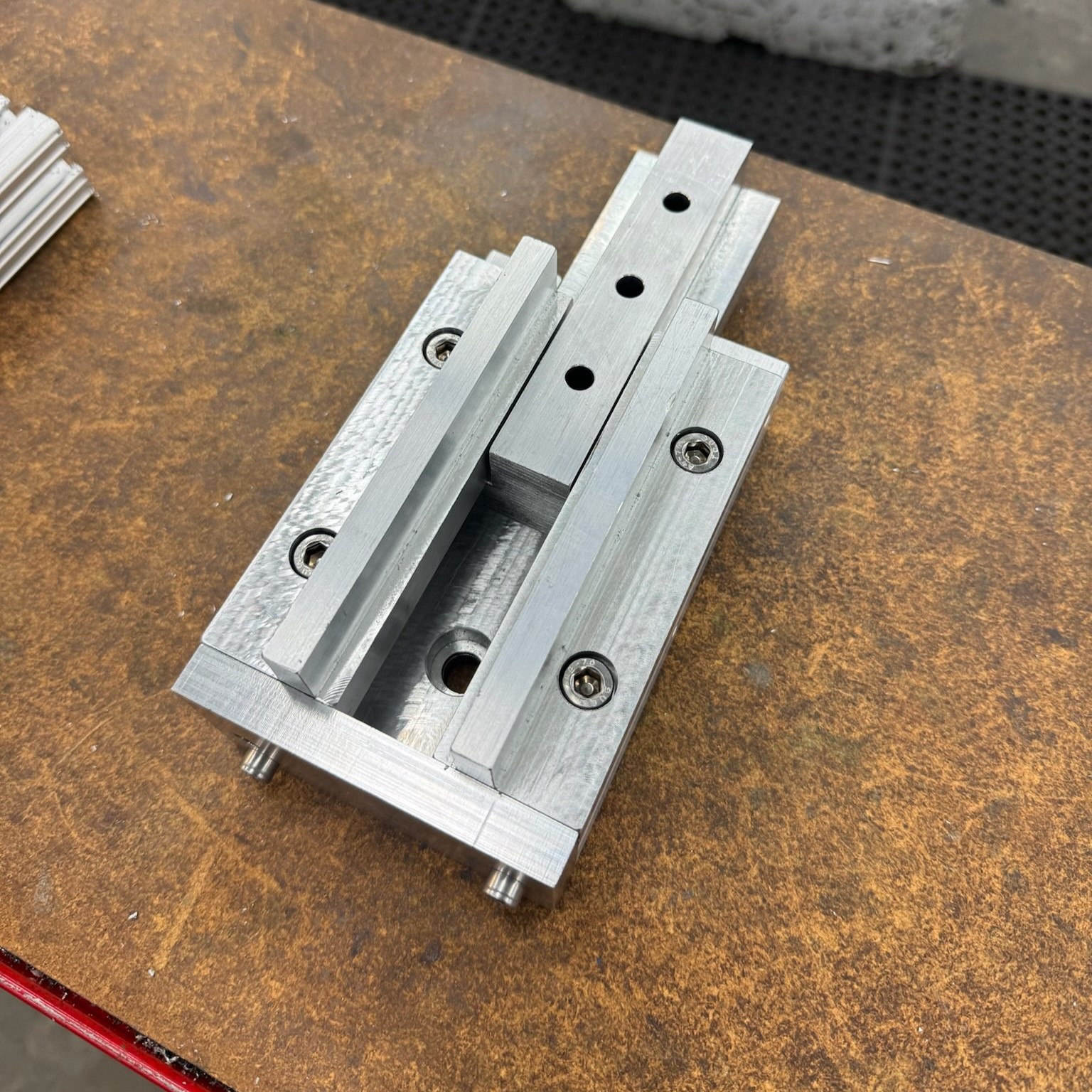

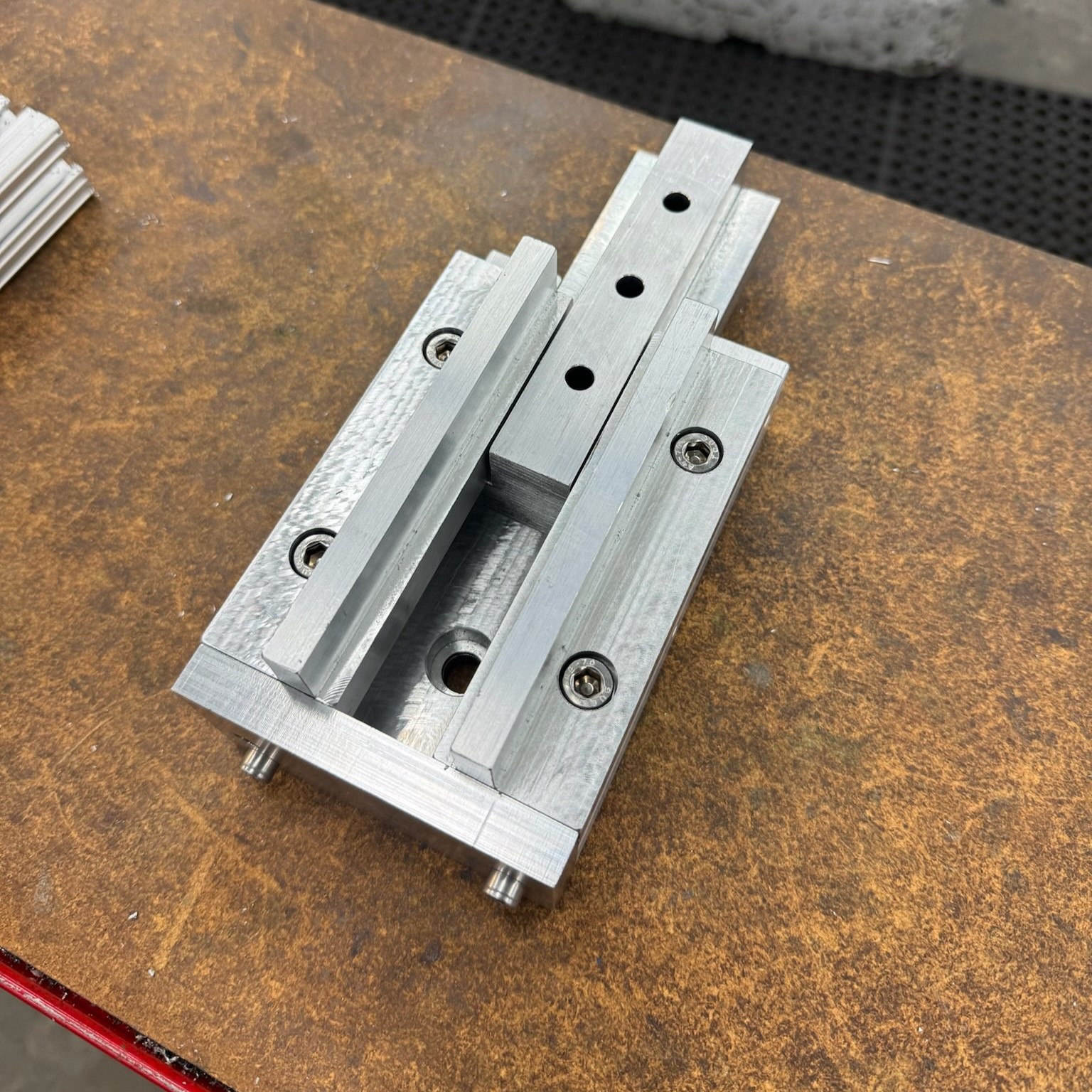

We used an aluminum extrusion to lock the entire assembly to the boat, 3D printed foil profiles for the length of the extrusion, and created a bracket mounting system to attach the

pod to the angeled extrusion.

All of these pieces were made from 6061 Aluminum for its corrosion resistance and were machined in our school's shop.