Sensible Robotics

View PresentationEngineer for Humanoid Robotics Test Rig

Skills: Fusion360, SLA, FDM, Silicone Molding, Procedural Analysis

Project Overview

This was a project in collaboration with startup robotics company, Sensible Robotics. I worked as an Engineering Consultant on a project where we were tasked to research, develop, and test silicone skin designs

optimal for humanoid robotics. Our three main objectives were:

1. Create an efficient test rig for skin design iterations

2. Design and mold the skin iterations

3. Use test rig to test skin patterns through 2 procedures to measure pattern efficacy in daily situations

I was the responsible engineer for developing the mechanical test rig which would enable our skin design team to test their different patterns and materials while keeping these constraints in mind:

1. Develop a mechanism capable of testing the gripping action of objects in a variety of orientations.

2. Ensure equal and consistent force across fingers when applying the "pinching" motion.

3. Ensure replicability of all settings of the test rig.

Design

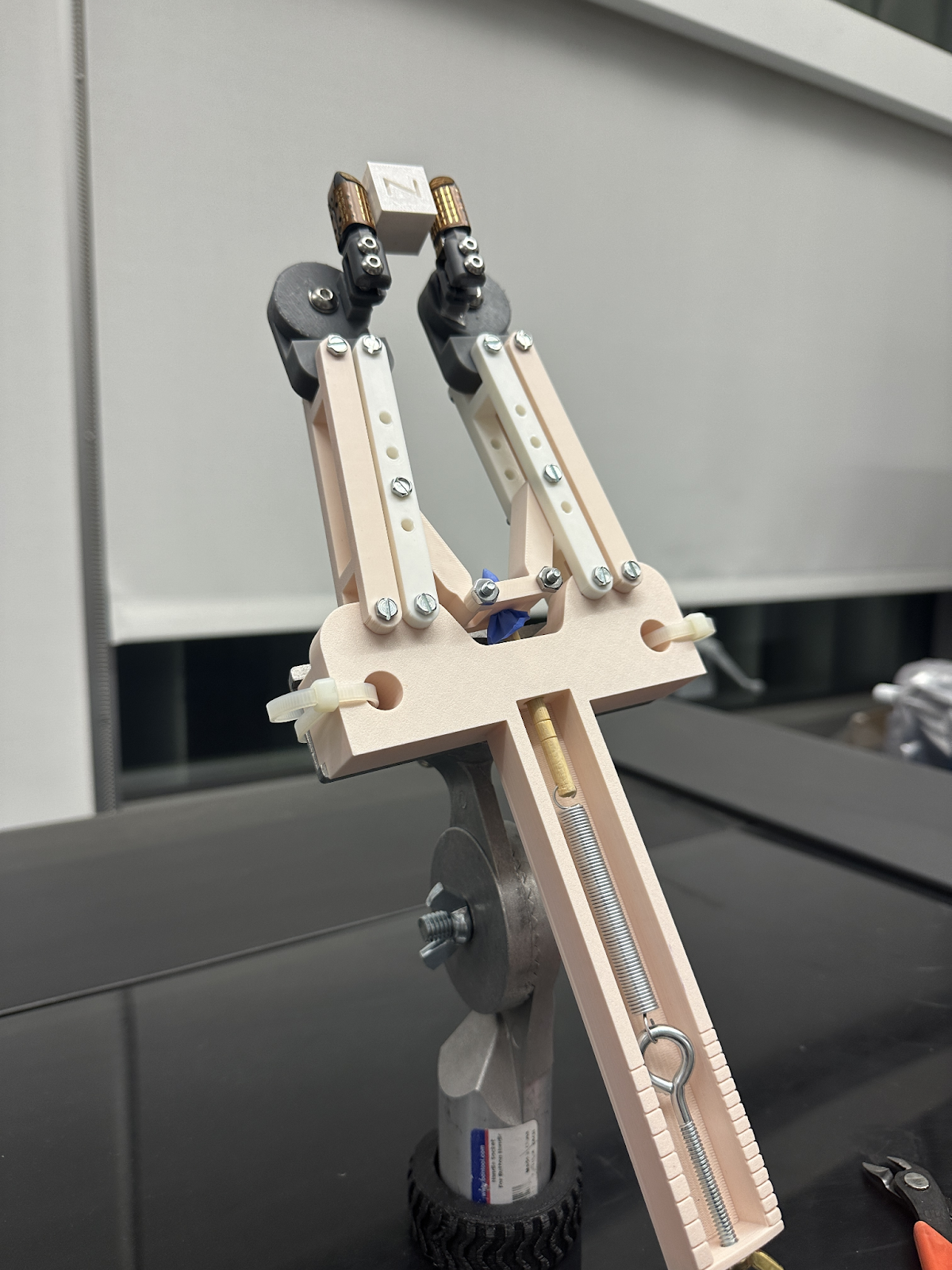

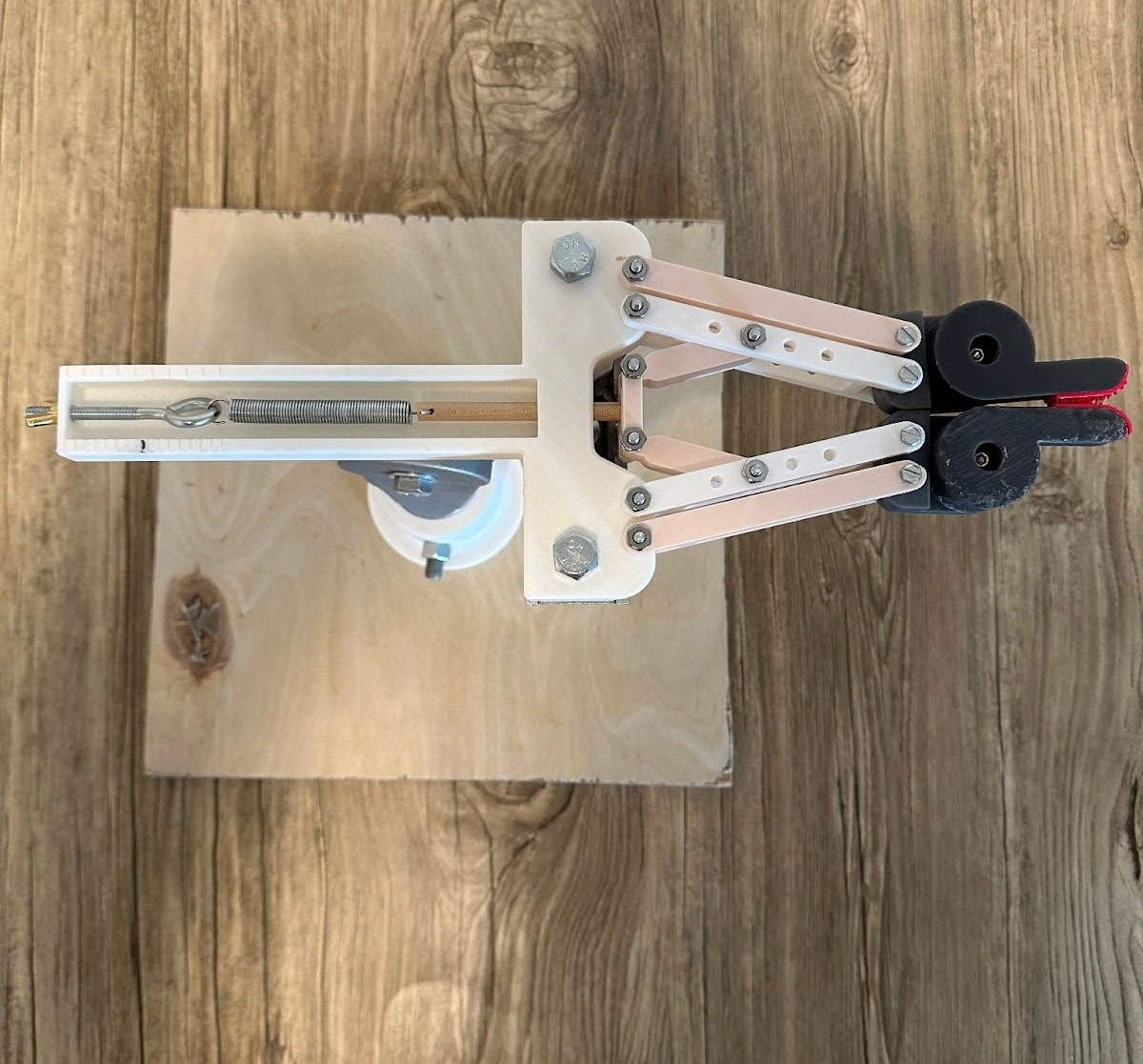

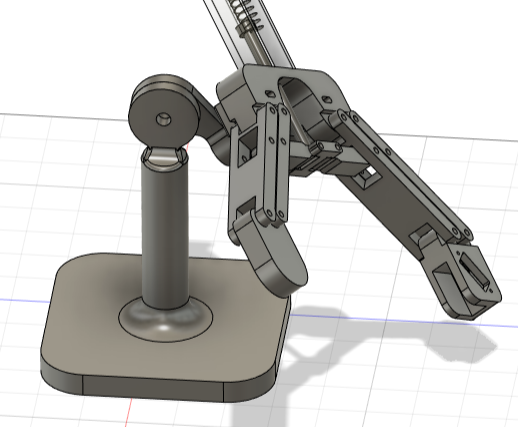

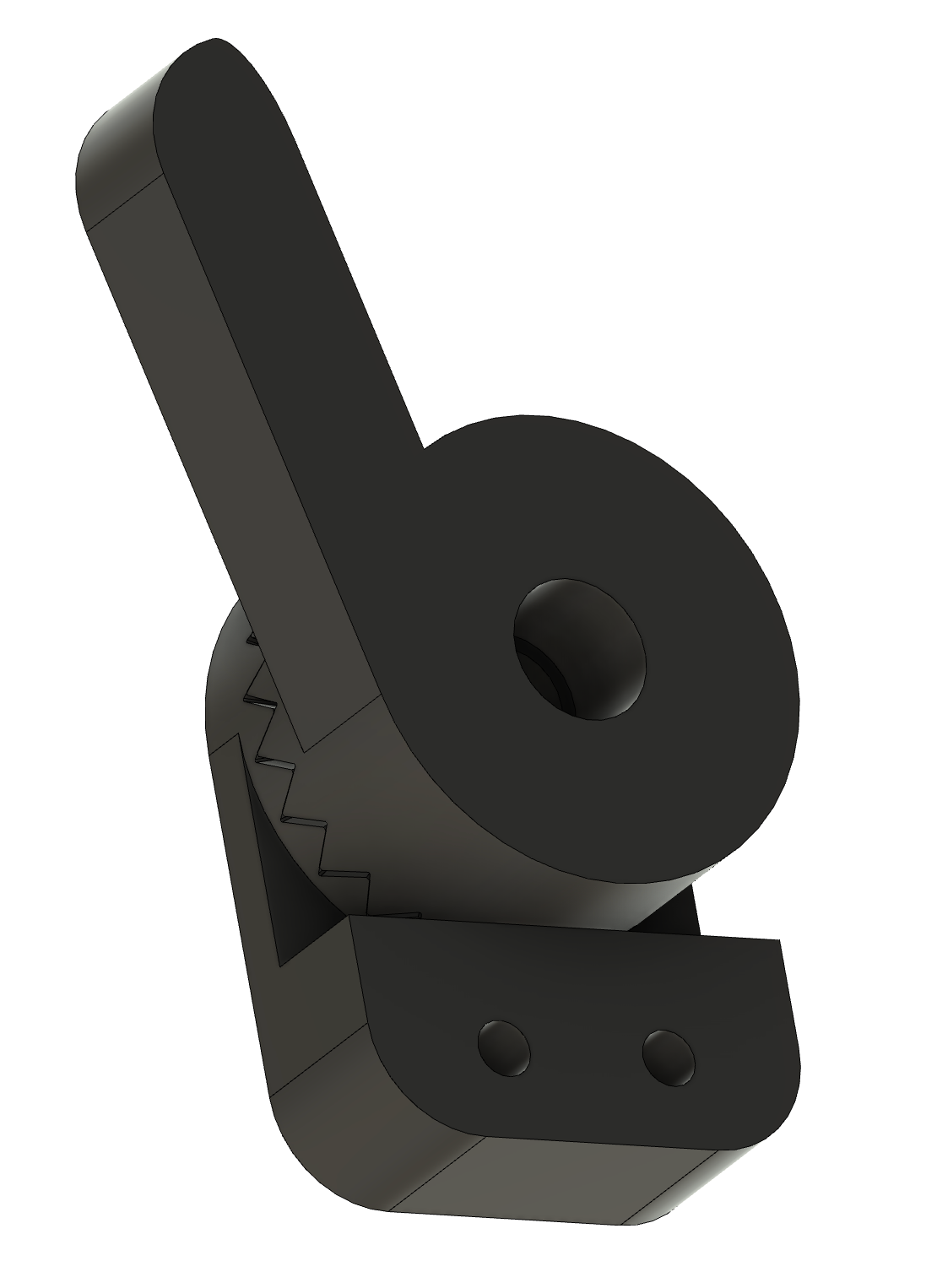

Initial brainstorming led us to create this underactuated gripping mechanism that allowed for us to iteratively test the skins while only having one test variable-- The angle of attack of the fingers. This would mean that the

only thing we would be changing between tests would be the angle at which fingers were coming together and gripping our test objects.

To ensure an equal application of force across two fingers, we developed a spring powered mechanism to provide calculatable force to the objects gripped within the rig. To create a wide range of test configurations that were easily replicable,

hirth joints were used to allow for rapid reconfiguration to a series of set points.

Our claw mechanism was closed at a natural state and could be manually opened to grip onto different test objects. The fingers were required to be parallel throughout the actuation of the rig. Our finger adjustment design was originally

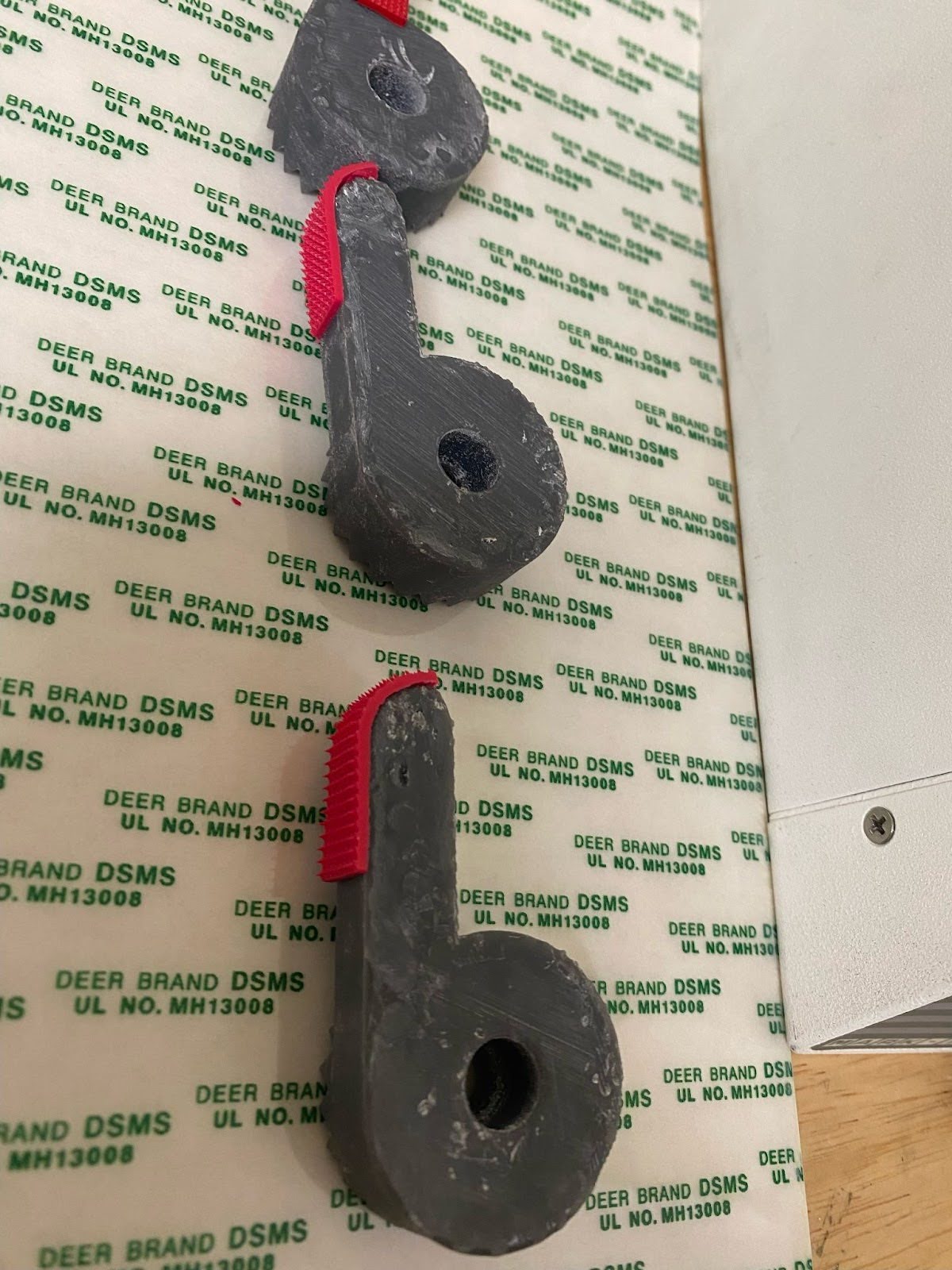

going to be motorized, but we felt this was inaccurate when acted upon by a force probe. The finger designs provided by Sensible were incorporated into the hirth joint system, allowing them to be mass produced via resin printing and easily

apply the skin designs (red silicone).

Our other team members created multiple skin designs inspired by common sports grips to biomimicry. We resin-printed molds and used silicone to produce the skins which were then attached to the fingers using pressure sensitive adhesives. We

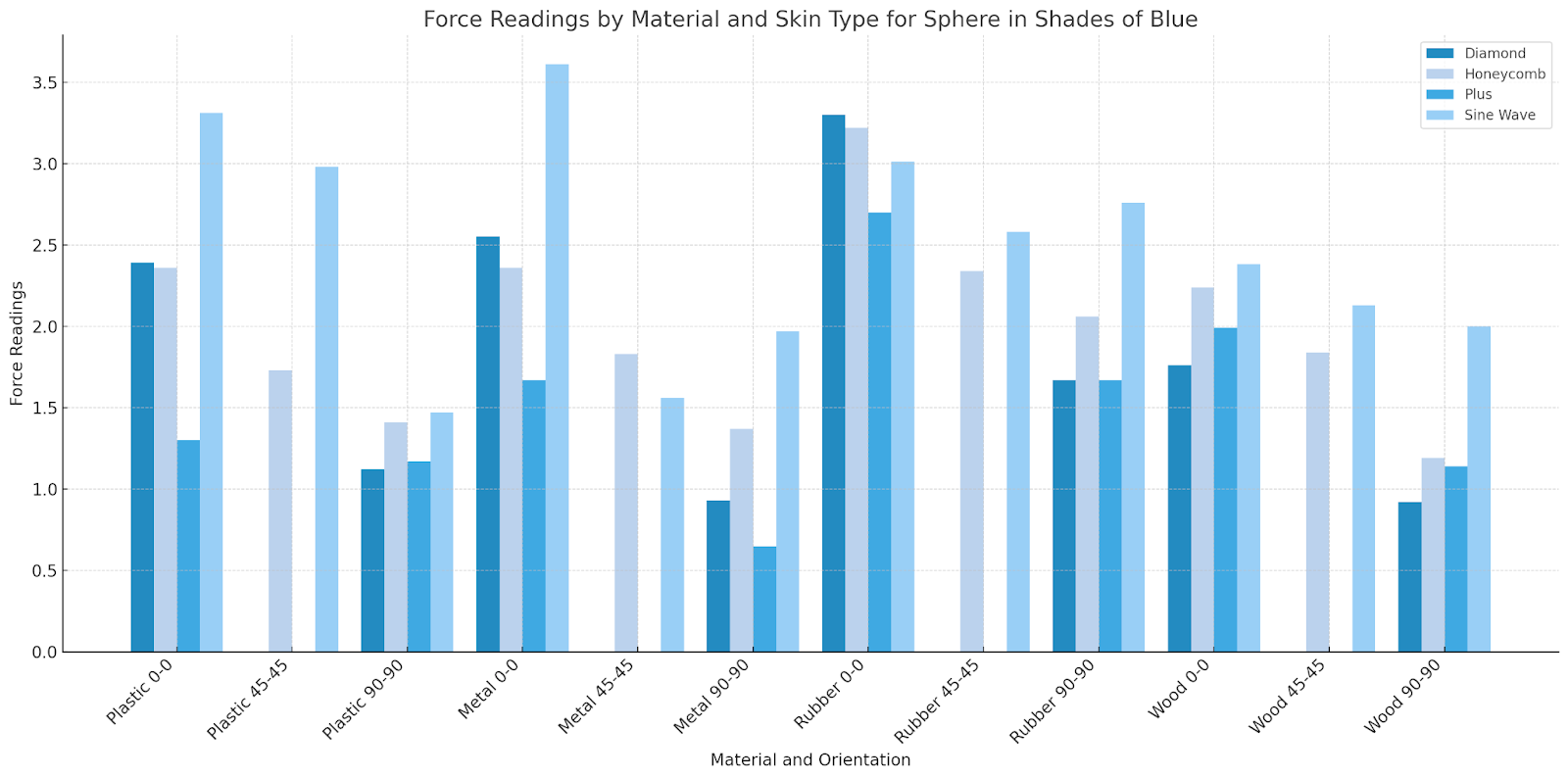

tested 4 different skin patterns and their performance in gripping onto metal plastic, rubber, and wooden test objects. To test the grip strength of each skin, we used a force probe to push out the objects from the fingers and recorded the highest force measurement.

Results

Our tests resulted in a clear winner of a fingerprint pattern similar to that of a human's. This design allowed for heightened grip onto metal, plastic, rubber, and wooden objects.